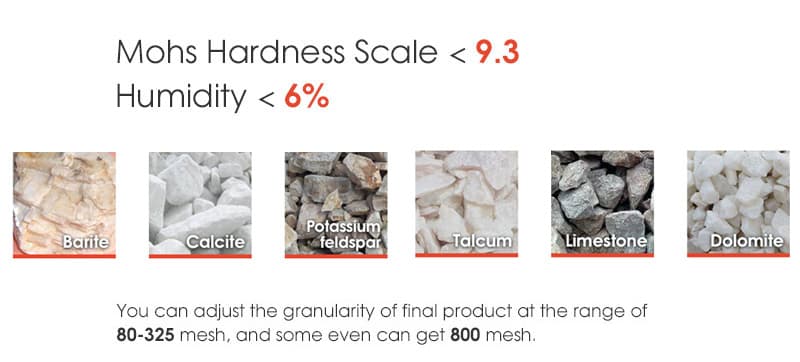

What Hardness Of Materials Is Suitable For Raymond Mill?

Raymond mill is widely used in the grinding of mineral products in the fields of metallurgy, building materials, chemical industry, mining, etc. It is suitable for high-fine powder processing various non-flammable and non-explosive materials with Mohs hardness below 7 and humidity below 6%. The finished product particle size can be adjusted arbitrarily within the range of 80-400 mesh, and some materials can reach 600 mesh. Through the combined action of the analyzer and the fan, it can meet the use requirements of different users.

The working principle of Raymond mill is based on the fact that the grinding roller rolls tightly on the grinding ring under the action of centrifugal force, and the material is sent to the middle of the grinding roller and the grinding ring by the scraper, and the material is crushed into powder under the action of rolling pressure. Then, the powdered material is blown up by the fan and passed through the analyzer for particle classification. The material that meets the fitness requirements passes through the analyzer and enters cyclone separator for separation and collection, while the material that doesn’t meet the fitness requirements returns the grinding chamber for further grinding. This equipment has the advantages of high crushing efficiency, low energy consumption, and adjustable crushing particle size, and is widely used in mining, metallurgy, chemical industry, building materials and other industries.

The working principle of Raymond mill is based on the fact that the grinding roller rolls tightly on the grinding ring under the action of centrifugal force, and the material is sent to the middle of the grinding roller and the grinding ring by the scraper, and the material is crushed into powder under the action of the rolling pressure. Subsequently, the powdered material is blown up by the fan and passed through the analyzer for particle size classification. The material that meets the fineness requirements passes through the analyzer and enters the cyclone separator for separation and collection, while the material that does not meet the requirements returns to the grinding chamber for further grinding. This equipment has the advantages of high crushing efficiency, low energy consumption, and adjustable crushing particle size, and is widely used in mining, metallurgy, chemical industry, building materials and other industries.

Regarding the hardness requirements of materials, Raymond mill is mainly suitable for the materials with a Mohs hardness below 9.3. Regarding the humidity requirements, the humidity of the material needs to be controlled below 6% to avoid affecting the processing effect due to excessive humidity. In addition, Raymond mill also has certain requirements for the maximum size of the material. The maximum size of the material is required not exceeding 30mm for the general model equipment, and not exceeding 35mm for the large equipment.

Send Email

Send Email Get Price List

Get Price List