Raymond Mill VS Ball Mill

Although Raymond mill and ball mill are both mining grinding equipment, they have significant differences in structure and application.

Different structures

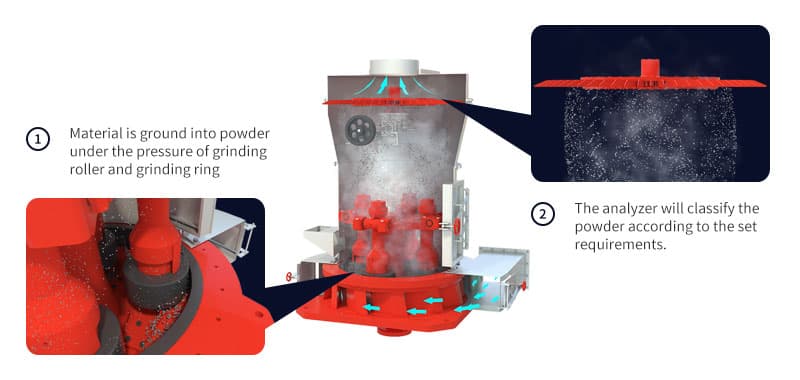

The whole structure of Raymond mill is composed of main machine, analyzer, pipeline device, blower, finished product cyclone separator, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electronic control motor, etc. The main machine of Raymond mill is composed of frame, air inlet volute, scraper, grinding roller, grinding ring, cover and motor.

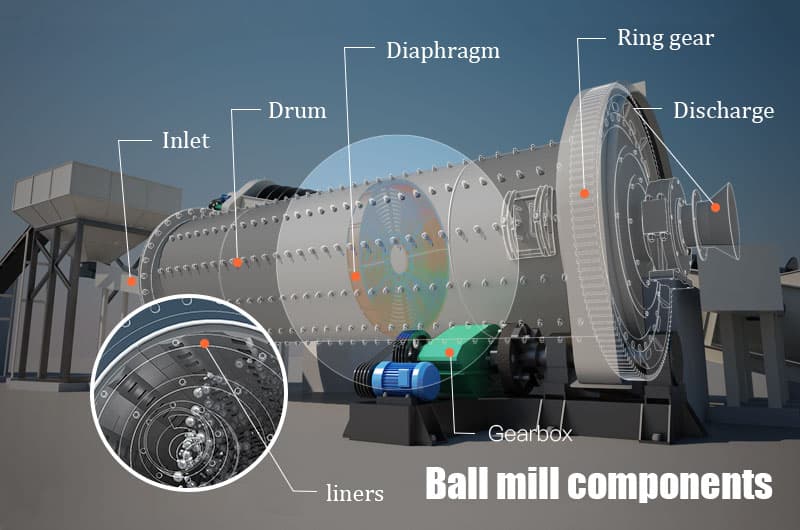

The ball mill is composed of main parts such as feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electronic control). The hollow shaft is made of cast steel, the inner lining is removable, the rotating large gear is made of casting hobbing, and the cylinder is inlaid with wear-resistant lining, which has good wear resistance.

Different application ranges

Raymond mill is widely used in the grinding and processing of mineral products in the fields of metallurgy, building materials, chemical industry, mining, etc. It is suitable for processing various non-flammable and explosive materials with Mohs hardness below 7 and humidity below 6%. The finished product particle size can be adjusted arbitrarily within the range of 80-400 mesh, and some materials can reach 600 mesh. Through the joint action of the analyzer and the fan, it can meet the use requirements of different users.

The ball mill is suitable for grinding various medium-hardness ores and other materials. It is a key mineral processing equipment for crushing materials after the materials are crushed. It is widely used in the production industries of building materials, chemicals, cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal beneficiation, glass and ceramics. According to the processing technology, it is divided into two grinding methods: dry and wet.

In fact, the two have many similarities, but there are also differences such as the above. Therefore, when selecting grinding equipment, the physical properties of the material, the requirements for material grinding, operating conditions, production environment, mechanical energy consumption, work efficiency and infrastructure investment should be comprehensively considered. A variety of factors can be compared and screened before making a decision.

Send Email

Send Email Get Price List

Get Price List