How To Choose A 200 Ton Per Hour Stone Crusher?

Generally speaking, an output of 200 tons per hour belongs to a medium-to-large stone production line. If it runs 20 hours a day, the daily output is about 4,000 tons. The stone crusher equipment that can meet the requirements includes jaw crusher, impact crusher, cone crusher, and heavy hammer crusher, which are large stone crushers. Of course, each type of crushing performance is different; according to different working principles, the types of crushers can be divided into impact crusher, cone crusher, jaw crusher and impact crusher (sand making machine), hammer crusher, etc. Crusher is mainly used to crush and shape soft, medium and hard stones.

Crusher is suitable for crushing various raw materials such as ores, cement, refractory materials, alumina clinker, diamond sand, glass raw materials, mechanical building materials, etc. It is widely used in smelting, mining, roads, building materials, railways and other industries. The following is an analysis of the classification and performance advantages of common crushing equipment for your convenience.

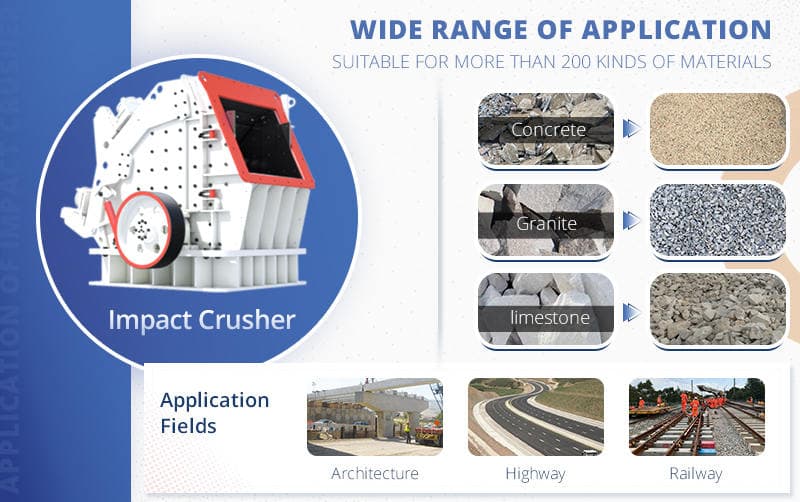

1. Impact Crusher

The impact crusher has a compact structure and a large crushing ratio. It is mainly used to crush medium-hard and brittle materials with a particle size between 120-500mm and a compressive strength not exceeding 320pa. It is generally used for secondary crushing.

The performance advantages are: large feed inlet, which can crush large pieces of material; deep crushing chamber, high production capacity; the drill bit of the wearing part is made of new materials and new technology, with good wear resistance, reducing the replacement frequency of wearing parts and increasing the service life of the impact crusher.

2. Cone Crusher

Cone crushers are mainly used to crush various mineral materials with hardness and above medium hardness. They are generally divided into spring cone crushers and hydraulic cone crushers, and are generally used for secondary crushing in stone production lines.

The performance advantages are: compact structure, good sealing, spring safety device, which can reduce downtime and ensure safe equipment operation; high production volume, simple operation and simple maintenance.

3. Jaw Crusher

Jaw crusher is mainly used to crush various materials with compressive strength not exceeding 320 MPa. It is used for primary crushing of stone production line. Jaw crusher is often in a leading position in stone production line, with many performance advantages such as good wear-resistant material structure, which not only ensures the wear resistance of vulnerable parts, but also prolongs the service life.

The equipment has a reasonable structural design and an adjustable discharge port, which improves the crushing ability of the crusher for different materials; the deep inner cavity design with no dead zone greatly improves the output of the jaw crusher.

4. Hammer Crusher

Stone can be crushed into shape in one step by hammer crusher, the feed opening is less than 1000mm, the discharge is fine, and it can be adjusted automatically. One device replaces three devices, reducing equipment costs by more than 60%.

It is an upgraded version of the small hammer crusher. The largest feed size is 1000mm, and the discharge size is automatically controlled. The finished particles have good shape and less stone powder. It is mainly used for stones with compressive strength below 200 MPa, such as limestone, bluestone, etc.

Crusher is an indispensable equipment in stone production line. my country's natural sand and gravel resources are very scarce. Although sea sand and desert resources are abundant, these sand and gravel cannot meet the needs of construction sand. Artificial sand is the most ideal high-quality material to replace natural sand. The emergence of artificial sand not only avoids a series of hazards caused by excessive exploitation of river sand, but also greatly enriches market demand;

Different stone crusher equipment has different prices. If you just want to crush stone, then the cheapest one is the jaw crusher, which is 400,000 or 500,000. If you want the finished particle shape, use it directly, and then choose the plastic impact crusher or heavy hammer crusher, which costs 600,000 or 700,000. But note that the material of the heavy hammer stone crusher is softer.

Send Email

Send Email Get Price List

Get Price List