Hammer Crusher VS Impact Crusher, Which One Is Better?

Which one is better, hammer crusher or impact crusher? This is a question that many users are entangled in when purchasing crushing equipment. Since both impact crushers and hammer crushers use high-speed impact to crush materials, and they are similar in appearance and have rotor structures, many people think that there is not much difference between the two types of equipment, so they are in dilemma when purchasing. In fact, these two types of crushers have their own advantages and disadvantages in terms of crushing capacity, finished product particle size and scope of application. The following is a detailed analysis.

1. Crushing chamber

The crushing chamber of the hammer crusher is small and its structure is well sealed, which can reduce dust pollution and ash leakage when crushing materials.

The crushing chamber of the impact crusher is relatively large, and the feed port is low and large. In this way, after the material enters the crushing chamber, it can collide with the impact plate repeatedly, and the force is more sufficient, so that large piecies of material can be better broken and the crushing efficiency is higher.

2. Finished product size

The hammer crusher adjusts the particle size of the finished product by adjusting the size of the gap in the screen plate, so the finished product has a small particle size and is mostly in powdery form.

The impact crusher can adjust the product particle size by adjusting the rotor speed or diameter, the size of the distributor opening, so the finished product particle size is uniform, generally cubic in shape, and has a low dust content.

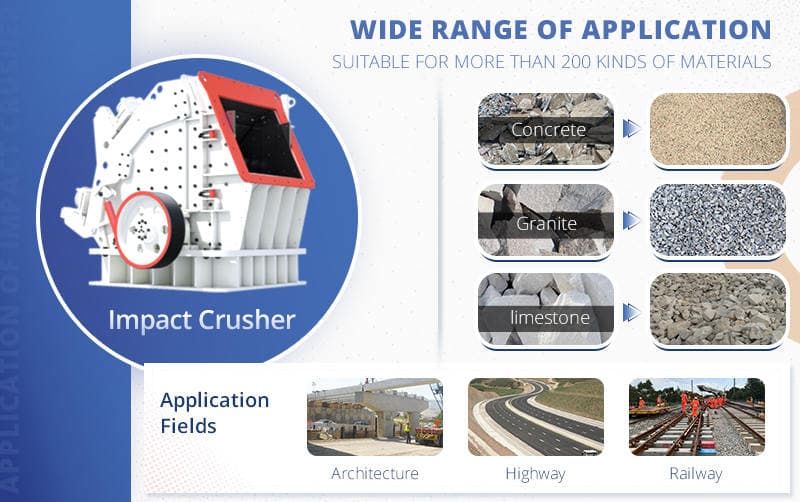

3. Scope of application

Hammer crusher is suitable for crushing soft and easily broken materials, such as coal, gypsum, limestone, etc. It is also suitable for crushing wood and paper with strong fiber structure, elasticity and toughness. It is mostly used in cement production lines or as limestone raw material crushing equipment, and can also be used as primary crushing equipment in sand and gravel co-production projects.

Impact crushers are suitable for most of the coarse and fine medium-hard materials with low iron content in the mining stone. They are mostly used as secondary crushing equipment in the crushing production line. At the same time, due to its uniform finished product particle size, it is widely used in railways, highways, and energy industries. For example, the anti-skid pavement of high-grade highways usually uses impact crushers as the final crushing equipment to produce concrete aggregates.

4. Input costs

Since the hammer crusher has a simple structure and operation, does not require primary or secondary crushing, is formed in one step, is cheap, and has a low initial cost. However, the rotor hammer plate and end plate are easy to break, and it also requires investment to replace parts later.

Relatively speaking, the price of impact crusher is higher than that of hammer crusher, and the initial investment cost is relatively high. However, it has a large crushing ratio, high crushing efficiency, strong interchangeability between parts, and fewer types of wearing parts, which reduces the occurrence of failures in the later working process. In the long run, impact crusher is also a good choice.

Through the above analysis, we hope that users can better understand the advantages and disadvantages of hammer crusher and impact crusher, and choose the equipment suitable for their own projects. If you still have doubts and don't know where to start, feel free to consult us.. We will arrange good engineers to answer your questions, design high-efficiency production lines, and select or customize high-efficiency equipment.

Send Email

Send Email Get Price List

Get Price List