What Is The Difference Between Soft Rock And Hard Rock Crushing? How To Choose A Crusher?

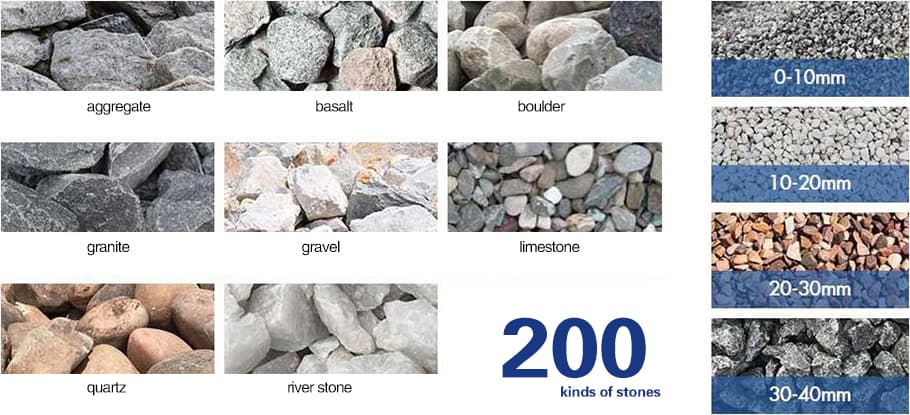

Hard rock mainly includes granite, basalt, river pebbles, cobblestone,etc., and its hardness is basically above 150 Mpa. Hard rock is difficult to crush and causes great wear on the crusher, so it is usually considered to use the jaw crusher and the cone crusher for preliminary crushing, and then use the impact crusher to shape the stone according to the requirements of the finished product to eliminate the needle-like and internal cracks produced in the stone during the crushing process. Finally, use a vibrarting screen for sorting to sort the crushed stone into finished sand and gravel aggregrates of various specifications.

Soft rock mainly includes limestone, weathered stone, sandtone, etc., and its hardness is below 150Mpa. The crusher for soft rock can be the jaw crusher, the impact crusher, and the hammer crusher. Also, according to the requirements of the finished product, an impact crusher can be used in the conjunction for shaping, which can eliminate the needle-like and internal cracks prosuced ib the stone during the crushing process and increase the output of machine-made sand.

When choosing a crusher, factors to consider include rock hardness, site conditions, finished product requirements, mud content, funds, and other factors. Specifically:

For hard rock, the cone crusher is suitable for processing high-hardness rock, such as granite, river pebbles, basalt, etc., because of its combined crushing characteristics of extrusion, shearing and grinding. This kind of crusher continuously moves the mortar wall toward the crushing wall, squeezing the material sandwiched between the two and crushing it.

For soft rock, the impact crusher and hammer crusher are more suitable. The impact crusher uses impact crushing, and the materials are repeatedly impacted and crushed between the plate hammer and the impact plate. It is suitable for processing rocks with medium and low hardness, such as limestone, calcite, etc. The sand and gravel materials prcessed by this crusher have uniform particle size, low needle-like content, and more reasonable grading.

In summary, the choice of crusher should be based on the hardness of the rock. The cone crusher is suitable for hard rock, while the impact crusher and the hammer crusher are more suitable for soft rock. In addition, factors such as the purchase cost of the equipment, the subsequent maintenance cost, and the adaptability of the site need to be considered.

Send Email

Send Email Get Price List

Get Price List