The Difference Between Ball Mill And Vertical Mill

Ball mill and vertical mill are two different grinding methods, and they have significant differences in many aspects.

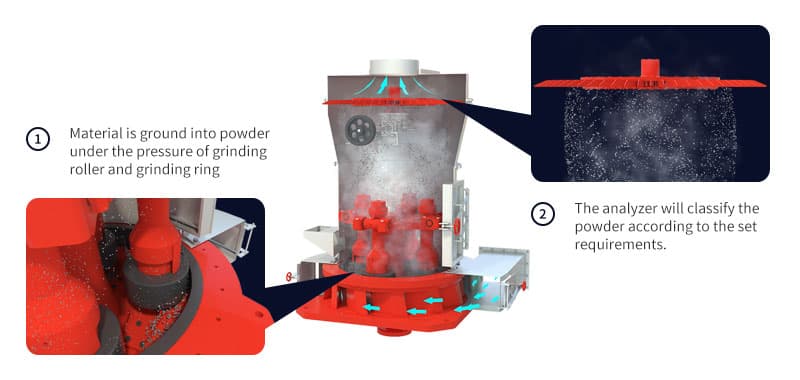

First, from the working principle, ball mill is to put the material into the ball mill and grind the material through the impact and friction between the steel balls. The vertical mill uses high-pressure gas and material to grind in the vertical mill. The high-pressure gas applies pressure to the material through the nozzle to break it.

Secondly, in terms of application scope, ball mill is mostly used for grinding operations in hydrometallurgy, mineral processing, cement, electricity, refractory materials and other industries. The vertical mill is widely used in building materials, electricity, chemical industry and other industries, especially in grinding cement raw materials.

In addition, from the perspective of energy consumption, the energy consumption of the vertical mill is lower than that of the ball mill. This is mainly because the grinding efficiency of the vertical mill is higher, and the grinding efficiency can be adjusted during the grinding process, thereby effectively reducing energy consumption. Although the ball mill can also adjust the grinding efficiency, its energy consumption is relatively high due to its structure and working principle.

Let's look at the impact on environmental pollution. The vertical mill is more environmentally friendly than the ball mill. Since the vertical mill adopts a closed grinding system, it can effectively reduce dust emissions and reduce environmental pollution. Although the ball mill also has certain environmental protection measures, its dust emissions are relatively large and its impact on the environment is also greater.

Finally, in terms of equipment structure, the vertical mill has a simpler structure, occupies a small area, and has a lighter weight. The ball mill has a more complex structure, occupies a large area, and has a heavier weight.

In summary, there are significant differences between ball mills and vertical mills in many aspects. The specific choice should be determined according to actual needs and conditions. If the material to be ground is hard and the production scale is large, you can consider using a vertical mill; if the material to be ground is soft and the production scale is small, you can consider using a ball mill.

Send Email

Send Email Get Price List

Get Price List