What Should Pay Attention To When Using Vibrating Feeder?

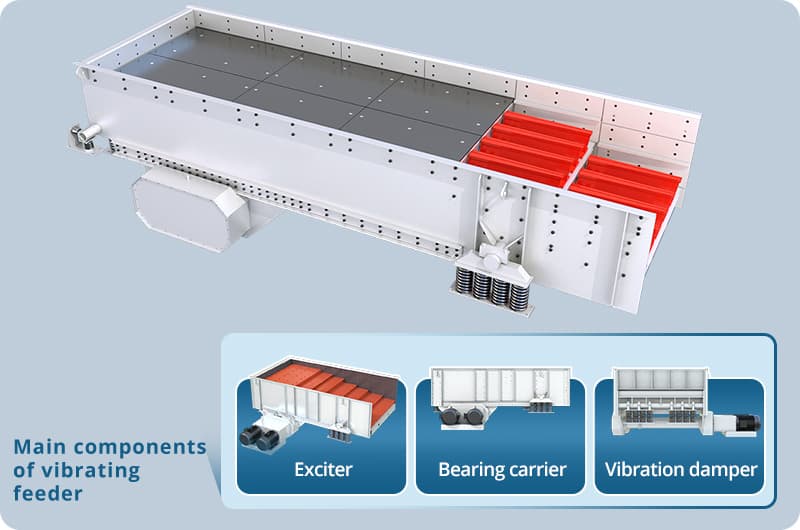

Vibrating feeder is an important auxiliary equipment in the production of machine-made sand and gravel. During production, the vibrating feeder can continuously and evenly deliver block or granular materials to the crushing equipment. The vibrating feeder is often matched with a jaw crusher. The working performance of the vibrating feeder not only has an important impact on the production capacity of the jaw crusher, but also has a great impact on the production efficiency of the entire production line.

During the use of the vibrating feeder, there will be some common problems, such as slow feeding, etc. The main reasons for the slow feeding of the vibrating feeder are as follows:

1. The inclination of the chute is not enough

Solution: Adjust the installation angle. Choose to raise/lower the fixed position of the two ends of the feeder according to the site conditions.

2. The angles of the eccentric blocks at both ends of the vibration motor are inconsistent

Solution: Check whether the two vibration motors are consistent and then adjust.

3. The vibration direction of the vibration motor is consistent

Solution: It is necessary to adjust the wiring of any one of the vibration motors to ensure that the two motors run in reverse and ensure that the vibration trajectory of the vibrating feeder is a straight line.

4. The exciting force of the vibration motor is not enough

Solution: It can be adjusted by adjusting the position of the eccentric block. The exciting force is adjusted by adjusting the phase of the eccentric block. One of the two eccentric blocks is fixed and the other is movable. Just loosen the bolts of the movable eccentric block. The exciting force is the largest when the two eccentric blocks coincide with each other, and then decreases in sequence; when adjusting, the eccentric blocks of the same group of motors should be in the same phase.

5. The support spring is easy to deform or damage

Solution: Choose a support spring with a certain toughness as the support of the feeder to avoid damage to the support spring due to excessive rigidity. Adjust the support spring and replace the damaged spring structure.

Send Email

Send Email Get Price List

Get Price List