Using Limestone To Produce Sand And Gravel Aggregate

Limestone is a carbonate rock with calcite as the main component. Sometimes it contains dolomite, clay minerals and clastic minerals, and has gray, gray-white, gray-black, yellow, light red, brown-red and other colors, and its hardness is generally not high.

Limestone artificial sand is made from limestone field waste, waste slag, stone powder, etc., through mechanical crushing, water washing and screening. The shape of artificial sand particles is mostly angular and the surface is rough, which is conducive to bonding with cement and other cementitious materials, and is conducive to improving the strength of concrete.

There are two main types of artificial sand and gravel production processes: two-stage crushing and three-stage crushing. Small artificial sand and gravel production lines mostly use two-stage crushing and screening processes. Some large artificial sand and gravel production lines use three-stage crushing and screening processes because of the large size of the materials.

Generally speaking, the production of limestone artificial sand mostly uses three-stage crushing, namely coarse crushing, medium and fine crushing, and sand making:

Coarse crushing generally uses jaw crusher

Medium crushing generally uses impact crusher

Fine crushing and sand making generally use vertical shaft crusher or cone crusher

1. Jaw crusher

Jaw crusher has the advantages of simple structure, high reliability of continuous operation, low price, etc., and the discharge port can be adjusted. Jaw crusher is not easy to clog when crushing wet materials and ores with high clay content. It is more suitable for processing sand and gravel aggregate raw materials and is often used in the coarse crushing stage.

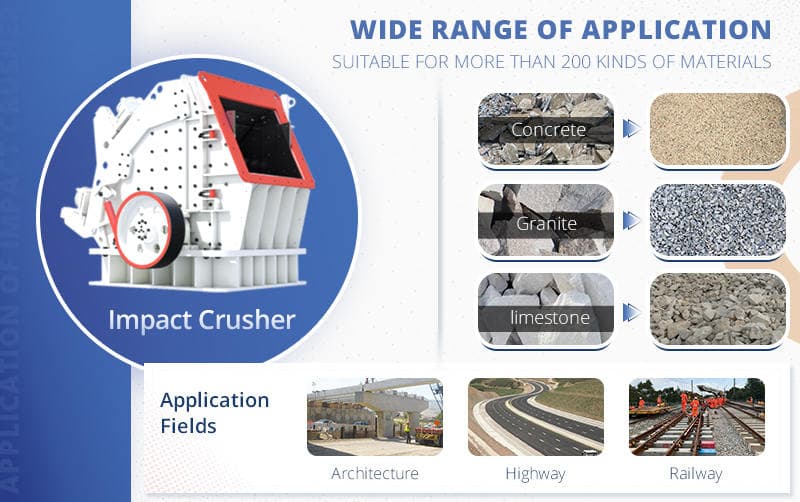

2. Impact crusher

Impact crusher has the characteristics of large crushing ratio and low energy consumption, which are more suitable for processing fragile materials. The product particle size of impact crusher is more uniform, and it is often used in the secondary crushing stage.

3. Vertical impact sand making machine

Vertical impact sand making machine has the advantages of small size, simple foundation, high crushing efficiency, large output, and low maintenance. The various cavity types of vertical shaft crusher under different working conditions are suitable for fine and ultra-fine crushing of most materials, taking into account the dual functions of shaping and sand making.

The above are the main crushing equipment used in the production of sand and gravel aggregates using limestone. How to configure the specific sand and gravel production line machinery and equipment should be analyzed according to specific problems. We are a leading mining equipment manufacturer in China and can provide customers with the best production line design solutions. Please contact us if you have any questions or needs.

Send Email

Send Email Get Price List

Get Price List