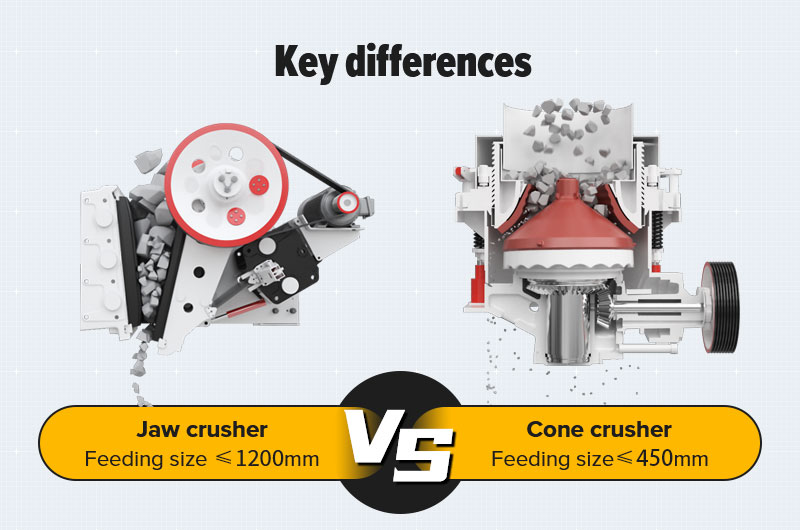

Differences Between Cone Crusher And Jaw Crusher

Cone crusher and jaw crusher are indispensable parts in stone crushing, sand making, grinding and other processes, but what is the difference between the two? The following is a detailed introduction to the difference between cone crusher and jaw crusher:

1. Jaw crusher

The jaw crusher is mainly composed of a frame, a movable jaw, a movable cone, a fixed cone, a liner, a screen plate, an adjustment device and an eccentric sleeve.

The movable jaw and the fixed jaw of the jaw crusher adopt stepless adjustment, and the up and down movement speed of the movable jaw can be adjusted according to the hardness and humidity of the crushed material to achieve the control of the particle size of the crushed material.

Application of jaw crusher:

It is mainly suitable for medium and fine crushing of materials, and can crush materials with a hardness between 200-1200; it can also be used to prepare construction and other artificial sand making, or in the mining and crushing process of steel slag and limestone in the metallurgical industry.

Working principle of jaw crusher:

The jaw crusher mainly uses the jaw plate to exert pressure on the material, and then makes the material move forward, and finally achieves the purpose of crushing.

Advantages of jaw crusher:

Jaw crusher has simple structure, reliable operation and low cost.

2. Cone crusher

The cone crusher consists of frame, movable jaw, movable cone, fixed cone, liner, screen plate, adjustment device and eccentric sleeve.

The movable jaw of cone crusher is a deformation of fixed jaw, which rotates with the movable cone shaft. In cone crusher, the gap change between movable jaw and fixed cone is mainly achieved by adjusting movable jaw and fixed cone. It can perform two different types of crushing: coarse crushing and medium crushing.

Application of cone crusher:

It is mainly used to crush materials with large crushing ratio, such as limestone, granite, etc.

Working principle of cone crusher:

The crushing principle of cone crusher is that after the material is crushed to a certain extent, the angle with the center hole changes, and it is affected by centrifugal force from large to small, and then falls along the center hole.

Advantages of cone crusher:

Good particle shape, precise control system regulation, optimized design and long service life.

The working principles of cone crushers and jaw crushers are different, and in the production process, the requirements of the two for materials are also different. This leads to great differences in their work. Therefore, it is recommended that when choosing a crusher, it is necessary to comprehensively consider factors such as the hardness of the raw materials, the output requirements, and the specific application scenarios.

Send Email

Send Email Get Price List

Get Price List