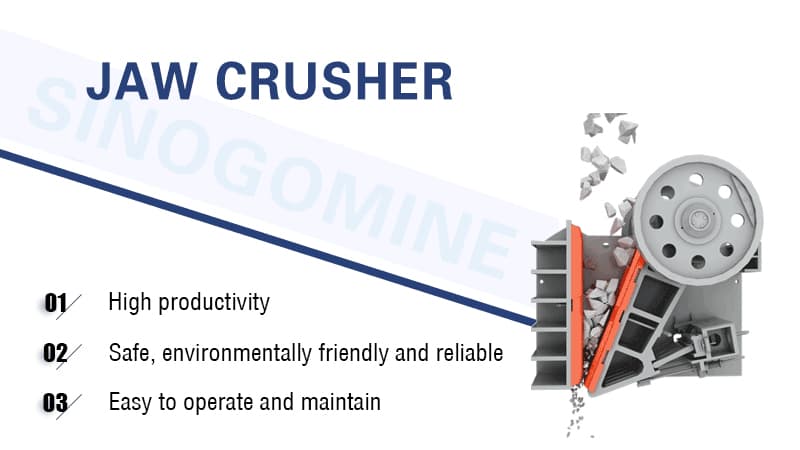

Jaw Crusher--Everything You Need To Know

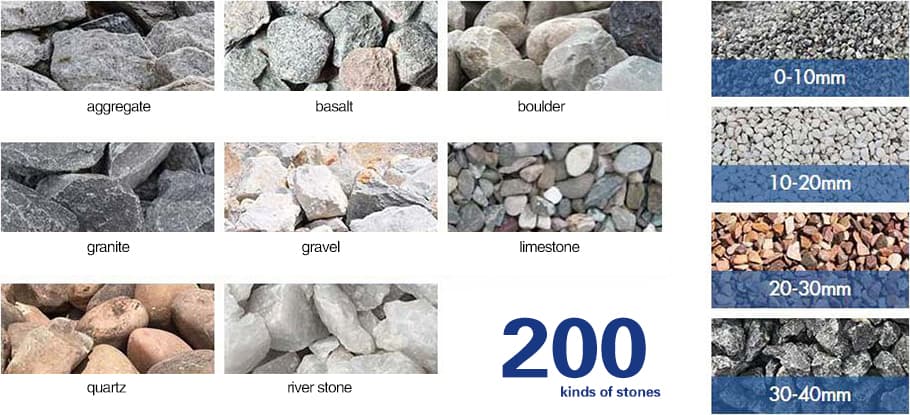

In material crushing, especially in the production of sand and gravel aggregates, crushing equipment is very important. There are many types of crushing equipment. Jaw crusher is a very widely used equipment, which is used for primary crushing, that is, coarse crushing of large pieces of materials.

The working principle of jaw crusher is very simple. The motor drives the pulley through the belt, and the eccentric shaft makes the movable jaw move up and down to squeeze and crush the material. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate to approach the fixed jaw plate, and the material is squeezed and crushed. As the motor rotates continuously, the movable jaw of the crusher moves periodically to crush and discharge the material, realizing mass production.

The scope of use of jaw crusher is extremely wide. Granite, basalt and other materials that are not only hard but also highly abrasive are not suitable for crushing with hammer crusher or impact crusher. The installation of gyratory crusher is complicated and the cost of use is high. Jaw crusher has become the first choice, with high cost performance and simple use and maintenance.

Jaw crusher is suitable for crushing various soft and hard materials. Common use areas include mining, construction solid waste recycling, pre-crushing under mines, etc., and the crushing effect is remarkable. In addition, jaw crushers are not only used in factories, but also installed in large quantities on mobile stations.

Send Email

Send Email Get Price List

Get Price List