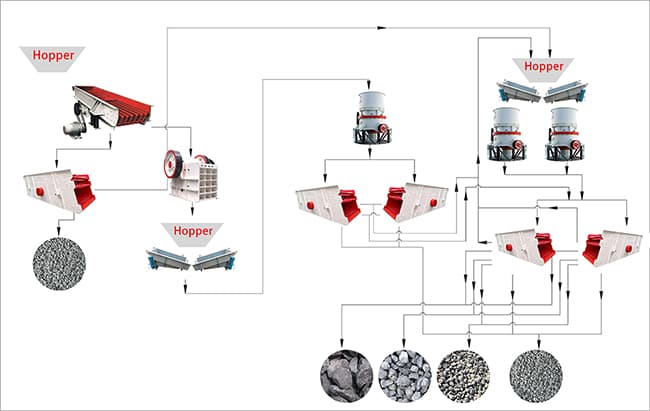

Granite Crushing and Sand Making Plant

-

Material: Granite

-

Max. Feeding Size: 1020mm

-

Output Size: 0-5mm, 5-10mm, 10-25mm, 25-38mm

Solution 1:Stationary solution

-

1.Vibrating Feeder deliver Granite into Jaw Crusher, separating soil and wastes at same time.

-

2.In Jaw Crusher, rock was crushed into <280mm, this is coarse crushing stage.

-

3.Stock Pile make sure Cone Crusher get the full cavity feeding.

-

4.<<280mm rock would be crushing again in first Cone Crusher, this is medium crushing stage.

-

5.Vibrating Screen separate discharging sizes into: >38mm, 5-38mm, 0-5mm.

-

6.5-38mm enter into next stage for further seprating, and >38mm deliver to second stage Cone Crusher for fine crushing, final output sizes: 0-5mm, 5-10mm, 10-25mm and 25-38mm.

Related Machines

Solution 2:Mobile solution

Mobile crushing solutions are also available! You just need to tell our engineer your demand, and we will equip you the right mobile crushers with low energy consumption, low cost, and high efficiency.

Gomine mobile crushing plant has exclusive benefits you cannot resist:

1. Easy access to constantly moving working environment

2. Shorter transportation time and lower installation cost

3. Versatile body combining alternative equipment, meet customers personalized needs

4. World-class quality, cutting-edge technology, Chinese price

5. Globalization customer site service 6. Easy to resale and higher resale value

Quick Way To Get Price

Please tell us your materials, capacity, You can get the price list and we will contact you asap, you can conctact us by email also.

(

(  (

(  (

(  (

(  (

(  Send Email

Send Email Get Price List

Get Price List