What Are Advantages Of Raymond Mill?

Raymond mill is widely used for the high-fine power processing in minerals, chemicals, construction, and other industries. Why is Raymond mill so popular in various industries? What are advantages of Raymond mill? Keep reding to figure it out.

Advantages of Raymond Mill

Highly Efficient

The Raymond Mill uses an advanced closed material flow design to achieve high efficiency output.

Compared with ball mills, Raymond mill can complete the same output faster and more efficiently because it do not need to stop frequently to reload or unload materials.

Wide Range of Applications

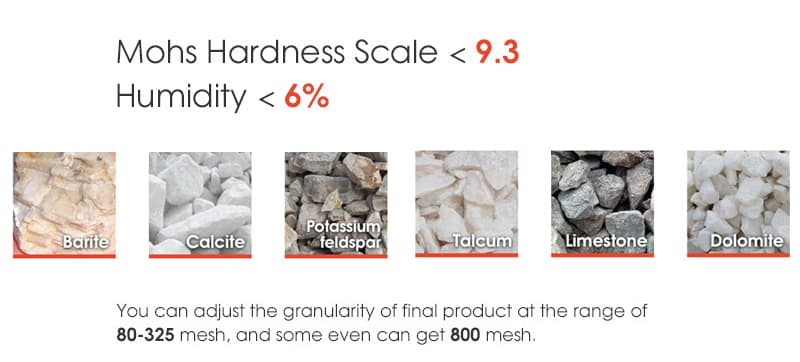

Raymond mills can grind a variety of materials and can be used for high-fine powder processing in minerals, chemicals, construction and other industries. Raymond mills can be used to process more than 280 materials, such as barite, calcite and feldspar, talc, marble, limestone, dolomite, fluorite, kaolin, cement, gypsum, glass, etc.

High Quality Output

Raymond mills can achieve fine and uniform particle size, which is critical for a variety of applications. And the fineness of the Raymond mill output can be easily adjusted, allowing customization according to specific needs.

Energy Saving

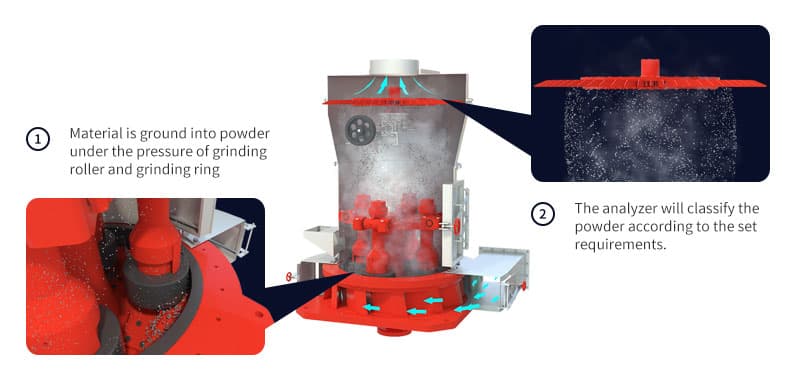

The design of the Raymond mill enables it to minimize energy consumption without affecting performance. The design of its grinding rollers and grinding rings enables the Raymond mill to process materials into fine powder in one go, achieving high grinding and reducing energy consumption.

Simple and Compact Structure

The design of Raymond mill is relatively simple, easy to install, operate and maintain.

In addition, the compact design of Raymond mill makes it take up less space, which can be easily used even if the facility space is limited.

Durable and Low Maintenance Cost

Raymond mill is designed for long-term use, and its construction uses solid high-quality materials to minimize the need for frequent repairs or replacements.

Conclusion

Raymond mill is efficient, high-yield, energy-saving, simple in structure, durable and has a wide range of applications, which makes it the first choice for many industrial applications that require fine grinding and crushing of materials.

Send Email

Send Email Get Price List

Get Price List